As a fellow vessel operator, I know one thing, that arranging it for flawless sailing can be a tough pill to swallow. But did you know now there is a program that is specially designed for this? Yes, it’s called a vessel planned maintenance system (PMS).

An article said “A PMS system on the ship is fast becoming a prerequisite today because planned management helps save time, effort, and costs.” (SHIP//MATE: Planned Maintenance System for Ships (PMS)).

This is such a great technology and in this write-up, I will tell you how you can optimize your vessel for smooth sailing with a marine planned maintenance system software. This is going to be an important post, so pay attention.

Designed as a consolidated platform, the vessel planned maintenance system (PMS) helps marine operators schedule, track, and control care operations over their fleet. To guarantee they run at maximum efficiency, the program automates basic chores including inspections, repair, and part replacements.

Having a digital PMS system will greatly simplify treatment services and reduce interruptions in a sector where equipment failures and delays might have expensive effects.

Conventional approaches to maintenance can depend on paper logs and manual scheduling, which leaves opportunities for human mistakes and missed deadlines. Designed to produce inspection schedules depending on manufacturer recommendations, operating data, and legal requirements, a vessel-planned overhaul machine automates the whole process.

Automated reminders and alarms help to lower the possibility of missed chores by guaranteeing the timely and deliberate execution of important repair works.

For vessel operators, following world maritime rules is vital. By use of automatic record-keeping and quick access to upkeep logs, PMS software guarantees that motorboats satisfy safety, environmental, and operational criteria.

Since all required documentation is kept orderly and easily accessible, regulatory inspections grow more effective. This not only lightens administrative tasks but also lowers the possibility of fines and penalties for non-compliance.

A vessel kept up properly is a safer vehicle. PMS systems monitor important assurance gadgets including emergency generators, fire suppression equipment, and communication circuits for condition.

Planned are regular inspections and maintenance to ensure these units are always completely operational. Improved safety precautions safeguard not only the cargo being carried but also the lives of crew members and passengers, therefore ensuring more dependable and trustworthy marine operations.

The ability of a vessel scheduled cleaning system to use data for predictive checks is among its most important benefits. PMS systems can find trends and possible problems by gathering and evaluating real-time equipment performance data, therefore preventing future failures.

By optimizing equipment lifetime and reducing unplanned breakdowns, predictive maintenance helps to cut general running expenses.

To monitor spare part availability, usage patterns, and reorder points, PMS software links with inventory control systems. This guarantees the constant availability of necessary spare parts, therefore preventing delays resulting from missing components.

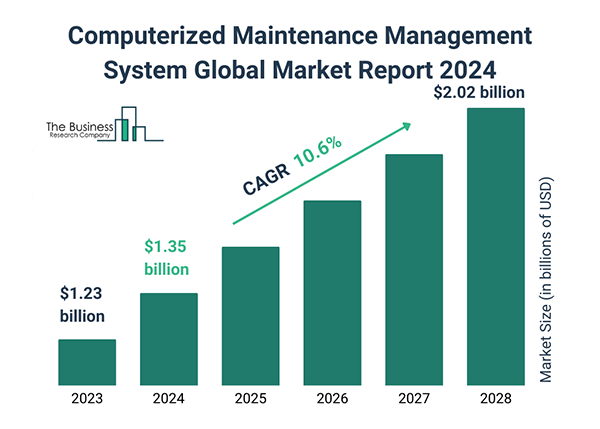

When stock levels are low, automated alarms alert operators, therefore lowering the demand for expensive shipping charges and emergency purchases. You might not realize it, but computer-based management systems are being used everywhere, and their market is expanding. Take a look at the graph below.

Both onshore and onboard, PMS protocols offer a consolidated platform whereby all preservation data is kept and easily available to authorized staff. For technical supervisors, shore-based support teams, and crew members, this promotes open communication and teamwork.

Easily shared maintenance chores, repair requests, and inspection reports enable coordinated efforts and prompt interventions. This is an important aspect as without it there won’t be any sync and things can take turns for the worse.

DID YOU KNOW?

Berge Olympus is considered to be the world’s most powerful sailing cargo ship!

Modern PMS arrangements let shore-based staff track vessel performance in real-time by use of remote monitoring tools. This feature guarantees fleet managers’ capacity to monitor servicing procedures, spot developing problems, and offer support without actually boarding.

Such a remote link improves restoration operations’ efficiency and offers a better view of the whole fleet’s state of condition. The benefits of a strong vessel planned maintenance system (PMS) are far-reaching and maximize engine efficiency, improve safety, and simplify processing.

Purchasing a specialized PMS solution guarantees that boats stay compliant, dependable, and efficient, in addition to helping to lower expenses and downtime. Adopting the benefits of a customized wellness system is a strategic action taken by shipowners and operators that guarantees long-term success and peace of mind.