I’ve been a warehouse manager for quite a long time, and I’ve seen a lot of development in this sector. Warehouses everywhere are making smart upgrades, and their main concern is getting the right tools and equipment. But how can you choose the best ones?

Famous TV personality Phil McGraw once said, “Sometimes you make the right decision, sometimes you make the decision right.” This is a powerful quote, but when it comes to product choosing, you can’t make a bad one flawless.

This is why I’m here to tell you how to transform warehouse efficiency with the right tools and equipment. Be attentive and note all the important things because I’ll mention everything that you should know.

We’ve been getting things done for ages, but methods changed and so did the machinery. Assignments were done more effectively and faster. Modern equipments are merged with the latest technologies which take their accuracy to the next level.

Warehouse requires a lot of labor, and doing it manually is dangerous and time-consuming. However, several new innovations have streamlined all the tasks for people and specific aids have been created for different tasks.

It saves your time, costs less, and requires limited human intervention. Not to mention, productivity has increased, and you can complete several things in a day. In the next heading, I will mention all the essential tools every factory needs.

If your distribution center has the best hardware, you’ll see some good changes. Some of the supplies or machines you must have are mentioned here:

Okay, so now you are aware of what you need to get, but how are you going to choose the best of the best? Well, don’t worry, in the next heading, I’ll break it down for you.

Now, it is time to find out how you can have the best equipment for yourself, just keep reading:

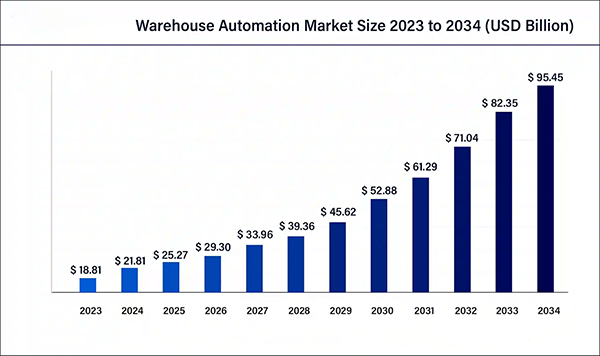

You have to know and keep these specifications in mind, only then you’ll be able to make the perfect purchase. If I’ll tell you about the stockroom equipment, you might be surprised by its worth. Take a look at the graph below.

As I said earlier, this modern solution for warehouses cuts costs and boosts productivity. You’ll be saving big bucks on labor charges and since most of the things will be done by machine, accuracy will also increase.

But you must have the applicable tools, not any tool will give you the same thing. If you invest in the wrong ones, it will only render things harder for you. Not to mention, inventory management will also be streamlined thanks to automation.

Specialized types of equipment are meant to make various tasks easier for you but don’t jump on directly operating it or giving it to amateurs. Instead, arrange proper training so that everyone can learn and use it properly.

Well-trained individuals can maximize its use, which will result in better performance. Besides, it is important that their safety is maintained, and they don’t exhibit any mistakes while operating anything.

DID YOU KNOW?

The first forklift was invented in 1917 by Eugene Bradley Clark, and it was known as Tructractor!

Everything changes when you get your workplace the perfect gear, machines, and devices, right? You get everything smooth workflow, tasks being done on time, reduced human errors, and whatnot.

So, what are you waiting for? If you want all these perks then you’ll have to accept, and I suggest you take professional advice so that you leave no room for any mistakes, rest these equipments is dangerous as well so be careful and be safe!