I’ve been an Industry facility manager for years and during this whole time, I see technology evolving and new things getting included, one of which was the Industrial climate control system. But what it is?

According to a case study, it is a part of HVAC (heating, ventilation, and air conditioning) systems have become an integral part of modern buildings and are designed to provide comfortable indoor environments while conserving thermal power and reducing carbon emissions. (ResearchGate: Review of HVAC Systems History and Future Applications).

But for the obvious reason, it consumes a lot of electrical power that can drain your pockets. Just so it doesn’t do that, I’m creating this article where I’ll talk about how to optimize your industrial climate control system for better energy saving. So, read carefully.

Proper maintenance and inspection are key to ensuring that whatever you are using is stable in the long run and that you can utilize it properly. This is no exception for industrial climate control systems.

You have to do tasks like checking refrigerant levels, calibrating sensors, and cleaning filters. With all this experience that I have, I can tell you one thing, if your engine or device is in top condition it will work more effectively and the electricity consumption will be minimal.

Another benefit of doing this is that in case there is any issue or potential threat, it could easily be dealt with before it causes any damage.

Upgrading to energy-efficient equipment will be your best move as it has several benefits. For starters, it will reduce your operating costs and power consumption. You’ll be saving big bucks thanks to it.

But not every electronic company will fit this standard, you’ll have to be careful and should go for brands like ENERGY STAR that are trusted by people and have a great image in the market.

Products should meet the necessary efficiency guidelines so that consumers don’t have to struggle with them or worry about the electricity bill.

Your industrial climate control machine heavily depends on temperature and humidity settings. If you set it to the appropriate temperature, its operational efficiency will be increased.

You’ll also be able to reduce workload from the system, and you should consider getting it checked by a dehumidification specialist so you can know the perfect level for all your needs.

Smart automation and controls can help you in various ways. Everything will be done on its own as it will adapt accordingly to the environment, which will result in energy savings and your overall machine performance will be in the best shape.

Gaining valuable insights with the help of smart controls can tell how much renewable power you are using. Based on the data, you can make changes accordingly so that it won’t be a headache in the future.

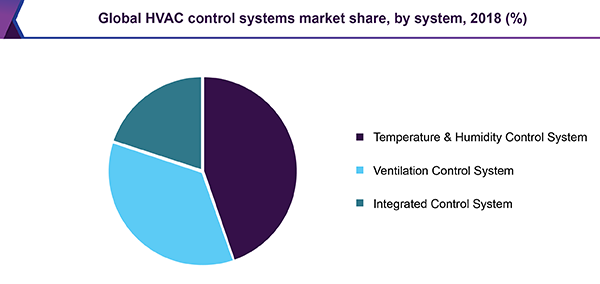

If you ask me about the US HVAS market share, it is mostly used as a temperature & humidity control product.

Your system gets heated as it gets used constantly without getting any proper breaks. In such cases, you can utilize thermal recovery appliances. You can reuse the captured heat, to reduce reliance and lower the cost of electric power.

These kinds of arrangements are proven to be effective, especially in those industries that work under high temperatures, as they produce more warmth. The best example of it is manufacturing and food processing.

If you didn’t know, then let me tell you that insulation and airflow management can improve energy consumption, and increase the efficiency of your industrial climate controls.

If you properly manage to insulate your facilities, it will prevent the temperature loss that usually happens during winter and gain warm air during the summer. A well-optimized airflow management will make sure that you get the peak performance.

DID YOU KNOW?

The HVAC market is worth around $183.57 billion!

Your staff and handling crew play a crucial role in ensuring that the industrial climate control systems are exceptionally efficient. This is why they should be well-educated on the topic so they can properly handle things.

Teach them about energy conservation, and provide all the essential tools and knowledge so they can start implementing what they have learned. This is an easy and effective way to achieve your goal.

I told you different ways that will help you with industrial climate control systems for better electrical savings. Those that I mentioned in the article are tried and tested, there are several other procedures you can do and try. But these supplies are dangerous, so always be careful around them. Be safe!